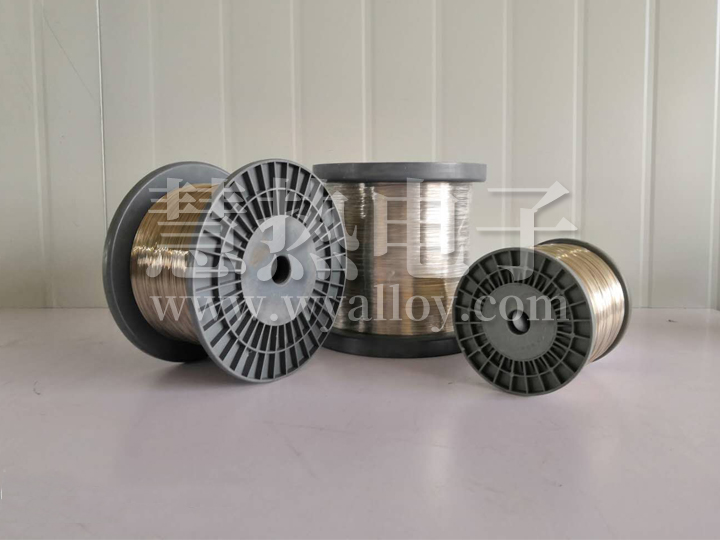

Products

Main uses:

Nickel-chromium alloy wires and strips belong to high resistance electrothermal alloys. They have lower thermal potential to copper, wider temperature range, better oxidation resistance and higher high temperature strength. They are mainly used for general wire-wound resistors, potentiometers, current limiting resistors and household electrothermal appliances, industrial electric furnaces and other heating elements, heating wires, etc. Resistance wire.

Chemical Constituents and Main Performance Parameters

|

Alloy

|

chemical composition%

|

|||||||||

|

C

|

P

|

S

|

Mn

|

Si

|

Cr

|

Ni

|

Ai

|

Fe

|

Other

|

|

|

≤

|

||||||||||

|

Cr20Ni80

|

0.08

|

0.02

|

0.015

|

0.60

|

0.75 ~1.60 |

20.0 ~23.0 |

more than

|

≤0.50

|

≤1.0

|

-

|

|

Cr15Ni60

|

0.08

|

0.02

|

0.015

|

0.60

|

0.75 ~1.60 |

15.0 ~18.0 |

55.0 ~61.0 |

≤0.50

|

more than

|

-

|

|

Cr20Ni37

|

0.08

|

0.02

|

0.015

|

1.00

|

1.00 ~3.00 |

18.0 ~21.0 |

36.0 ~39.0 |

|

more than

|

-

|

|

Cr20Ni35

|

0.08

|

0.02

|

0.015

|

1.00

|

1.00 ~3.00 |

18.0 ~21.0 |

34.0 ~37.0 |

|

more than

|

-

|

|

Cr20Ni30

|

0.08

|

0.02

|

0.015

|

1.00

|

1.00 ~2.00 |

18.0 ~21.0 |

30.0 ~34.0 |

|

more than

|

-

|

|

Cr10Ni90

|

0.08

|

0.02

|

0.015

|

0.30

|

1.00 ~2.00 |

9.0 ~11.0 |

余

|

-

|

≤1.0

|

-

|

Main Physical Properties of Electrothermal Alloys

|

performance

|

Maximum Service Temperature of Components°C

|

Melting point (approximation)°C

|

density g/cm3

|

resistivity(20°C)

μΩ·m |

specific heat j/g.°C |

Thermal conductivity KJ/m.n.°C |

Average Line

(20~ 1000°C) α×10-6/°C

|

organization

|

magnetic

|

|

Alloy

|

|||||||||

|

Cr20Ni80

|

1200

|

1400

|

8.40

|

1.09 ±0.05 |

0.440

|

60.3

|

18.0

|

austenite

|

Nonmagnetic

|

|

Cr15Ni60

|

1500

|

1390

|

8.20

|

1.12 ±0.05 |

0.494

|

45.2

|

17.0

|

austenite

|

Nonmagnetic

|

|

Cr20Ni37

|

1100

|

1390

|

7.90

|

1.04 ±0.05 |

0.500

|

43.8

|

19.0

|

austenite

|

Nonmagnetic

|

|

Cr20Ni35

|

1100

|

1390

|

7.90

|

1.04 ±0.05 |

0.500

|

43.8

|

19.0

|

austenite

|

Nonmagnetic

|

|

Cr20Ni30

|

1100

|

1390

|

7.90

|

1.04 ±0.05 |

0.500

|

43.8

|

19.0

|

austenite

|

Nonmagnetic

|

|

Cr10Ni90

|

1100

|

1427

|

8.70

|

0.70 ±0.05 |

0.460

|

-

|

29.0

|

austenite

|

Nonmagnetic

|

Note: The tables in this paper are for reference only and are subject to the national standards. If users need special requirements and other specifications, they can customize according to the samples or other technical requirements. The above standards are implemented GB/T 1234-1995。

- 2019-05-29 > Manufacture and Use Characteristics of Resistance Alloy Wire

- 2019-05-22 > Suggestions on Testing and Selection of Alloy Wire by Technical Departments

- 2019-05-15 > Annealing and Application of Precision Resistance Alloy Wire

- 2019-05-08 > Strict quality standards should be met in the manufacture of high performance alloy products

- 2019-05-01 > High Temperature and Corrosion Resistance of Alloy 600 Wire

- 2019-04-24 > What are the differences between the use of solid resistance wires and resistance alloy wires?

- 2019-04-17 > What unique functions do copper-nickel alloys have?

- 2019-04-10 > Application of Wire Alloy in Special Environment

- 2019-04-03 > Development of Aluminum Alloy Wire for Automotive Fasteners

- 2019-03-27 > Alloy Making and Use of Compensation Wire